Composite materials

Composite materials, as the name suggests, are new materials with better overall performance than the original constituent materials, prepared by the composite process of two or more materials with different properties and forms. Because of its light weight and high strength, composite materials have many advantages that ordinary single materials do not have, so the application of composite materials are becoming more and more widespread, such as aerospace, electrical and electronic, automotive and other fields, playing a pivotal role in both military and civilian applications.

Due to their unique structural characteristics, as well as the process technology used in the manufacture of the parts, and other factors, composite materials inevitably develop defects and damage, which can affect their performance and structural integrity, and reduce their service life. Therefore, it is vital to use industrial CT technology to inspect composite materials.

Raysov industrial CT, with its intuitive CT images and grayscale images corresponding to the material, geometry, components and density of the workpiece, not only provides information on the shape, location and size of defects, but also, in combination with density analysis techniques, can determine the nature of defects, making it easier and more intuitive to solve the problems of spatial localization, attempted quantification and comprehensive characterization of defects that have long plagued NDT inspectors.

Industrial CT images fully reproduce the compositional properties of the workpiece material, so that 3D industrial CT images are of practical importance for the analysis of complex structural parts inspection, and industrial CT can be combined with CAD, CAM and other manufacturing technologies to form the so-called reverse engineering. All these advantages are not available in other NDT techniques, so industrial CT technology is a common method for inspecting composite materials.

01 Industrial CT detection of porosity defectsThe porosity of composite materials is due to the lack of preheating in the raw material which leads to a large content of moisture and volatiles, air entrapped in the curing process and undischarged volatilization which produces porosity and is the result of a less than perfect production process.

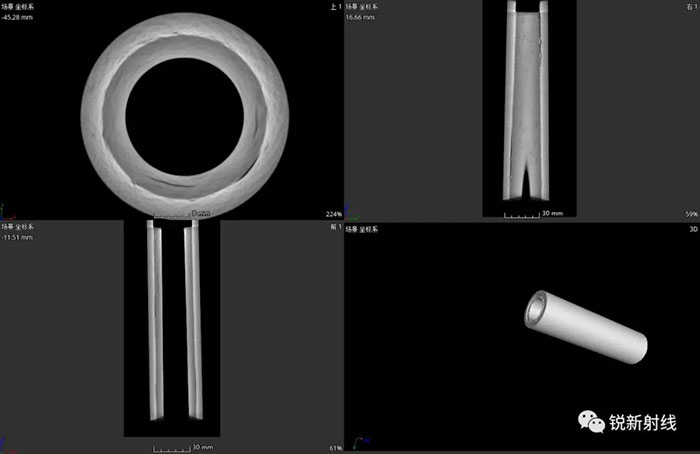

Industrial CT imaging of porosity defects appear as black dot-like, oval or circular black areas with smooth contours and distinct boundaries.

02 Industrial CT detection of entrapment defectsThe main reasons for inclusions in composite materials are: impurities in the raw material fiber prepreg or self, impurities accidentally brought in during operation, etc.

Industrial CT imaging of the entrapment defects are manifested as medium gray shiny parts, such as: speckled, blocky, bar shape, etc.. For entrapment defects, after industrial CT processing can get the size of internal entrapment, shape location and other situations.

03 Industrial CT detection of crack defectsCracks in composite materials are caused by the joint action of internal pressure and external processing pressure. Cracks that appear only on the surface of composite materials are light, while more serious cracks are not only deeper and wider, but may even expand until the whole composite material.

Crack defects in industrial CT imaging appear as thin black strips of lines with different depths and widths and lengths.

04 Industrial CT detection of delamination defectsDelamination of composite materials refers to the delamination and cracking between layers. It has a decisive impact on the quality of composite products and is a serious injury or damage.

Delamination defects in industrial CT imaging appear as either continuous or intermittent irregular patterns in black.

05 Industrial CT detection of cascading defectsThe generation of composite material string layer is mainly due to the extrusion and deformation of the outer material and the inner material, which destroys the formed material film layer.

The cascading layer in industrial CT imaging is shown as a white cloudy shape.

Raysov Industrial CT Imaging Inspection System

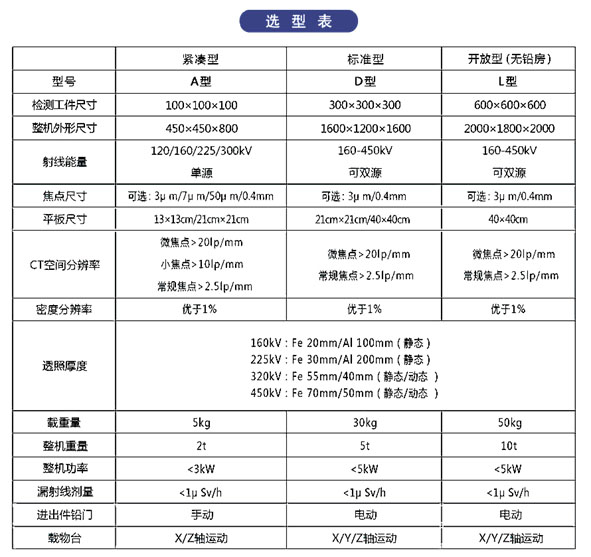

Raysov industrial CT imaging inspection system is an inspection system developed for high-end quality control and analysis of composite materials of different sizes and dimensions, based on many years of application experience.

Four highlights1. Breakdown of application requirements to provide the best price/performance ratio

2. Smallest nanometer focus available

3、Adopt German VGstudio 3D visualization and analysis technology

4. Full marble platform for high precision and repeatability